FEATURES

Universal 90 - 264VAC or 120 - 370VDC Input voltage

Accepts AC or DC input (dual-use of same terminal)

Operating ambient temperature range: -30℃ to +70℃

High I/O isolation test voltage up to 4000VAC

Low ripple & noise

Output short circuit, over-current, over-voltage, over-temperature protection

DIN rail TS-35/7.5 or 15 mountable

Suitable for small chassis and narrow space installation

Safety according to CE, BS EN62368

ND-75-48 is Mornsun AC-DC converter series featuring a cost-effective, energy efficient green power supply solution for standard DIN-rail mounting. The products offer a high level of stability and immunity to noise for industrial control equipment, machinery, and other industrial equipment in a variety of harsh environments. These light weight AC-DC converters have an extremely compact design and the standard rail installation for space saving. With good EMC performance, compliant with international , EN62368 standards for EMC and safety.

Selection Guide | ||||||

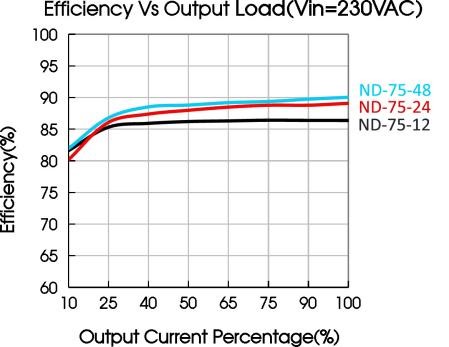

Certification | Part No. | Output Power (W) | Nominal Output Voltage and Current (Vo/Io) | Output Voltage Adjustable Range (V) | Efficiency at 230VAC (%) Typ. | Max. Capacitive Load (µF) |

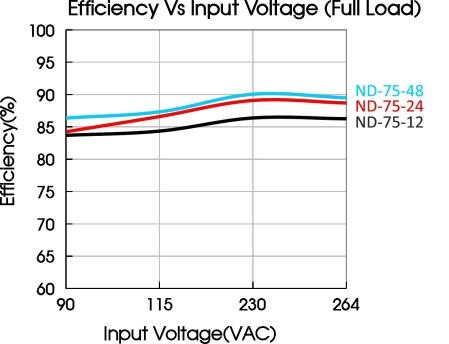

EN/BIS | ND-75-12 | 75.6 | 12V/6.3A | 12-14 | 86 | 6000 |

ND-75-24 |

76.8 | 24V/3.2A | 24-28 | 89 | 1500 | |

ND-75-48 | 48V/1.6A | 48-53 | 90 | 1000 | ||

Input Specifications | ||||||

Item | Operating Conditions | Min. | Typ. | Max. | Unit | |

Input Voltage Range | AC input | 90 | -- | 264 | VAC | |

DC input | 120 | -- | 370 | VDC | ||

Input Voltage Frequency | 47 | -- | 63 | Hz | ||

Input Current | 115VAC | -- | -- | 2 |

A | |

230VAC | -- | -- | 1 | |||

Inrush Current | 115VAC |

Cold start | -- | 25 | -- | |

230VAC | -- | 45 | -- | |||

Leakage Current | 240VAC | <0.5mA | ||||

Hot Plug | Unavailable | |||||

Output Specifications | ||||||

Item | Operating Conditions | Min. | Typ. | Max. | Unit | |

Output Voltage Accuracy |

Full load range | 12V | -- | ±2.0 | -- |

% |

24V/48V | -- | ±1.0 | -- | |||

Line Regulation | Rated load | -- | ±0.5 | -- | ||

Load Regulation | 0% - 100% load | -- | ±1.0 | -- | ||

Ripple & Noise* |

20MHz bandwidth (peak-to-peak value) | 12V | -- | -- | 80 |

mV |

24V | -- | -- | 120 | |||

48V | -- | -- | 150 | |||

Temperature Coefficient | -- | ±0.03 | -- | %/℃ | ||

Minimum Load | 0 | -- | -- | % | ||

Hold-up Time | 115VAC | 12 | -- | -- |

ms | |

230VAC | 60 | -- | -- | |||

Short Circuit Protection | Recovery time < 3s after the short circuit disappear. | Constan tcurrent,continuous,self-recovery | ||||

Over-current Protection | Normal temperature | 105% - 150% Io, constant current mode, automatic recover after fault condition is removed | ||||

Low temperature, high temperature | ≥105%Io, constant current mode, automatic recover after fault condition is removed | |||||

Over-voltage Protection | 12V | ≤17V (Output voltage turn off, re-power on for recover) | ||||

24V | ≤33V (Output voltage turn off, re-power on for recover) | |||||

48V | ≤60V (Output voltage turn off, re-power on for recover) | |||||

Over-temperature Protection | Output voltage turn off, re-power on for recover after the temperature drops. | |||||

Note: *The “Tip and barrel method” is used for ripple and noise test, output parallel 47uF electrolytic capacitor and 0.1uF ceramic capacitor, please refer to Enclosed Switching Power Supply Application Notes for specific information. | ||||||

General Specifications | |||||||

Item | Operating Conditions | Min. | Typ. | Max. | Unit | ||

Isolation Test | Input - |

Electric strength test for 1min., leakage current <10mA | 2000 | -- | -- |

VAC | |

Input - output | 4000 | -- | -- | ||||

Output - | 500 | -- | -- | ||||

Insulation Resistance | Input - |

At 500VDC | 50 | -- | -- |

MΩ | |

Input - output | 50 | -- | -- | ||||

Output - | 50 | -- | -- | ||||

Operating Temperature | -30 | -- | +70 |

℃ | |||

Storage Temperature | -40 | -- | +85 | ||||

Storage Humidity |

Non-condensing | 10 | -- | 95 |

%RH | ||

Operating Humidity | 20 | -- | 90 | ||||

Switching Frequency | -- | 65 | -- | kHz | |||

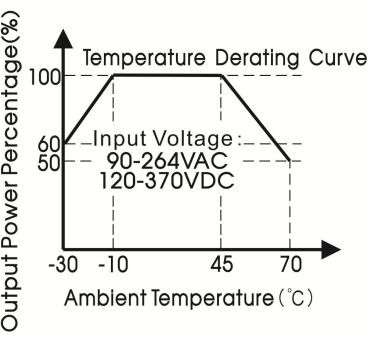

Power Derating | Operating temperature derating | -30℃ to -10℃ | 2.0 | -- | -- |

%/℃ | |

+45℃ to +70℃ | 2.0 | -- | -- | ||||

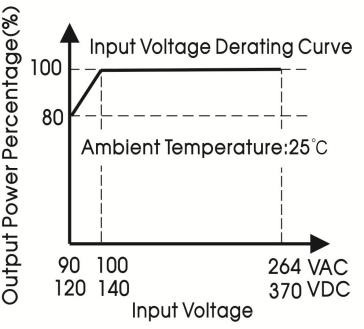

Input voltage derating | 90VAC - 100VAC | 2.0 | -- | -- | %/VAC | ||

Safety Standard | IS13252 (Part1) safety approved & EN62368-1 (Report) Design refer to BS EN 62368-1 | ||||||

Safety Class | CLASS I | ||||||

MTBF | MIL-HDBK-217F@25℃ | ≥300,000 h | |||||

Mechanical Specifications | |

Case Material | Metal (AL1100, SGCC) |

Dimensions | 32.00 x 125.00 x 87.50mm |

Weight | 350g (Typ.) |

Cooling Method | Free air convection |

Electromagnetic Compatibility (EMC) | |||

Emissions | CE | CISPR32/EN55032 CLASS B | |

RE | CISPR32/EN55032 CLASS B | ||

THD | IEC/EN 61000-3-2 CLASS A | ||

Immunity | ESD | IEC/EN 61000-4-2 Contact ±6KV/Air ±8KV | perf. Criteria A |

RS | IEC/EN 61000-4-3 10V/m | perf. Criteria A | |

EFT | IEC/EN 61000-4-4 ±2KV | perf. Criteria A | |

Surge | IEC/EN 61000-4-5 line to line ±2KV/line to ground ±4KV | perf. Criteria A | |

CS | IEC/EN61000-4-6 10 Vr.m.s | perf. Criteria A | |

Voltage dips, short interruptions and voltage variations immunity | IEC/EN61000-4-11 0%, 70% | perf. Criteria B | |

Product Characteristic Curve:

Note:

1. With an AC input voltage between 90 -100VAC and a DC input between 120-140VDC the output power must be derated as per the temperature derating curves;

2. This product is suitable for applications using natural air cooling; for applications in closed environment please consult Mornsun FAE.

Note:

1. Unless otherwise specified, parameters in this datasheet were measured under the conditions of Ta=25℃, humidity<75% RH with nominal input voltage and rated output load;

2. All index testing methods in this datasheet are based on our company corporate standards;

3. In order to improve the efficiency at high input voltage, there will be audible noise generated, but it does not affect product performance and reliability;

4. We can provide product customization service, please contact our technicians directly for specific information;

5. Products are related to laws and regulations: see "Features" and "EMC";

6. The out case needs to be connected to PE ( ) of system when the terminal equipment in operating;

7. The output voltage can be adjusted by the ADJ, clockwise to increase;

8. Our products shall be classified according to ISO14001 and related environmental laws and regulations, and shall be handled by qualified units;

9. The power supply is considered a component which will be installed into a terminal equipment. All EMC tests should be confirmed with the final equipment. Please consult our FAE for EMC test operation instructions.